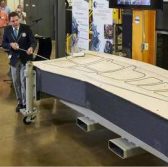

A trim-and-drill tool created by researchers at the Energy Department‘s Oak Ridge National Laboratory for Boeing has set a new Guinness World Record as the largest solid three-dimensionally printed item.

A trim-and-drill tool created by researchers at the Energy Department‘s Oak Ridge National Laboratory for Boeing has set a new Guinness World Record as the largest solid three-dimensionally printed item.

ORNL said Monday the laboratory worked over 30 hours to print the tool that is 17.5 feet long, 5.5 feet wide and 1.5 feet tall with a weight of approximately 1,650 pounds.

Boeing will use the trim tool to secure the composite wing skin of the company’s 777X passenger jet and subsequently provide feedback to ORNL, the laboratory added.

“The existing, more expensive metallic tooling option we currently use comes from a supplier and typically takes three months to manufacture using conventional techniques,” said Leo Christodoulou, Boeing director of structures and materials.

Christodoulou added the additively manufactured trim tool will work to address energy, time, labor and production requirements as well as align with Boeing’s strategy to use 3D printing technology in production areas.

Boeing plans to begin 777X production in 2017 while deliveries will start in 2020.