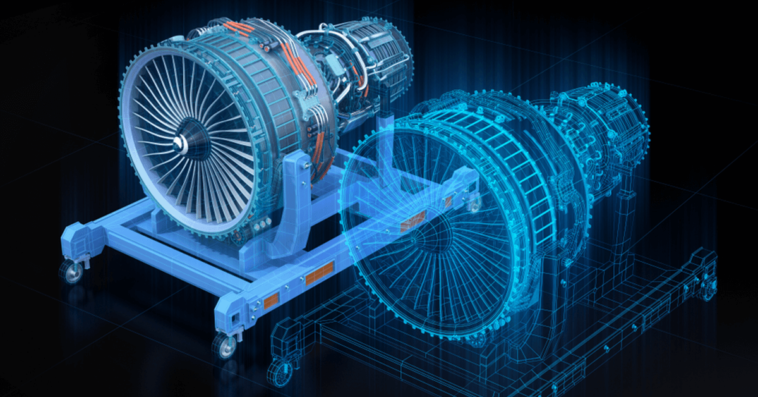

Digital twins, or computerized renderings of real-life systems and objects, are now favored by private companies and the government alike to test and gain a deeper understanding without having to make physical modifications, which can be costly and time consuming. Scott James, senior scientist at Noblis, said that one thing that distinguishes digital twins from other kinds of modeling is that they are “living entities.”

“The real system is going to evolve. And part of the digital twin being effective is making sure that the evolution of that system goes in tandem with that digital twin,” James described during ExecutiveBiz’s virtual Digital Twins Forum on Wednesday.

The government and private sector’s top technologists will be present at Potomac Officers Club’s Defense R&D Summit on Jan. 31. Join us to hear keynote addresses from Under Secretary Heidi Shyu and Chief of Naval Research RDML Kurt Rothenhaus, among other fascinating sessions. Register here now!

James participated in a panel discussion moderated by Siemens Government Technologies Vice President Kristin Cochran alongside two representatives from the Department of Defense. During the discussion, Cochran defined digital twins as “a view of a product at a point in time… a snapshot of an asset along its lifecycle.” She said this is distinct but related to digital thread tech, which is understood as “how we’re moving process and data and flow and all activities related to that asset that we want to capture in time over its lifecycle,” a more fluid conception that aligns with James’ thoughts.

Travis Mueller, product lead for transformation within the U.S. Army’s XM-30 Program Office, said that the service branch is doing its best to transition away from a physical modeling methodology for fleets of prototype vehicles and other projects that could take up to five years. Instead, they are turning toward “what we can achieve in the digital realm and…verify through limited tests,” Mueller stated.

However, Mueller and Steven Turek, technical director of the Department of the Air Force’s Digital Transformation Office, agreed that there are generational disagreements that sometimes prevent a full-scale embrace of tools like digital twins. Mueller said older members of the Army “are very resistant to the change” and Turek attested that trusting the technologies is a big stumbling block for certain officials, a trend that correlates with culture and age.

Despite the intermittent resistance, though, the biggest believers within the Army, Air Force and other DOD components are exploring digital twins’ applicability in a variety of tasks. Among them, modeling and simulating how vehicles perform as well as their potential role in manufacturing and predictive analytics.

Right now, Muller said, digital twin advocates — and acolytes of digital modernization broadly — in the DOD are attempting to move past marveling at the novelty of these movements as a “cool fad” and and break down what they actually mean and how they can positively impact systems that are 50 years old.